IR Line Following Robot

Project Constraints

Implement line-following behavior using a minimum of three IR reflectance sensors (cameras and alternative sensing modalities were not permitted)

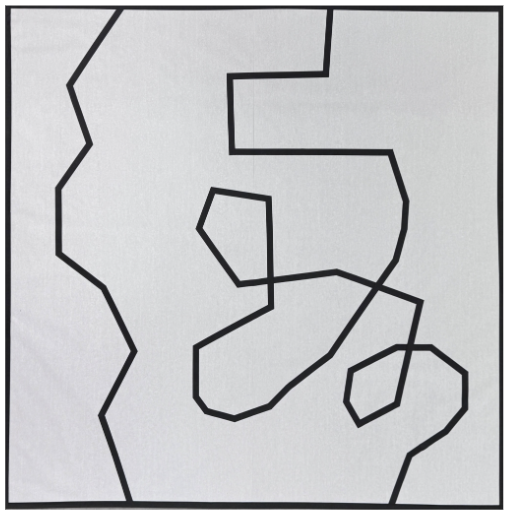

Follow one of two predefined track layouts, one of which is designed with tight turns, intersections, and 90-degree turns

Design and fabricate a custom robot chassis from scratch

The robot had to be constructed and demonstrated within one week

Additional Self-imposed Constraint

Fully implement a 5+ sensor array that does PID control with well-tuned gains

Use LiPo battery for power, so the robot is untethered

Prototyping and Understanding Components

Prototype Design Process:

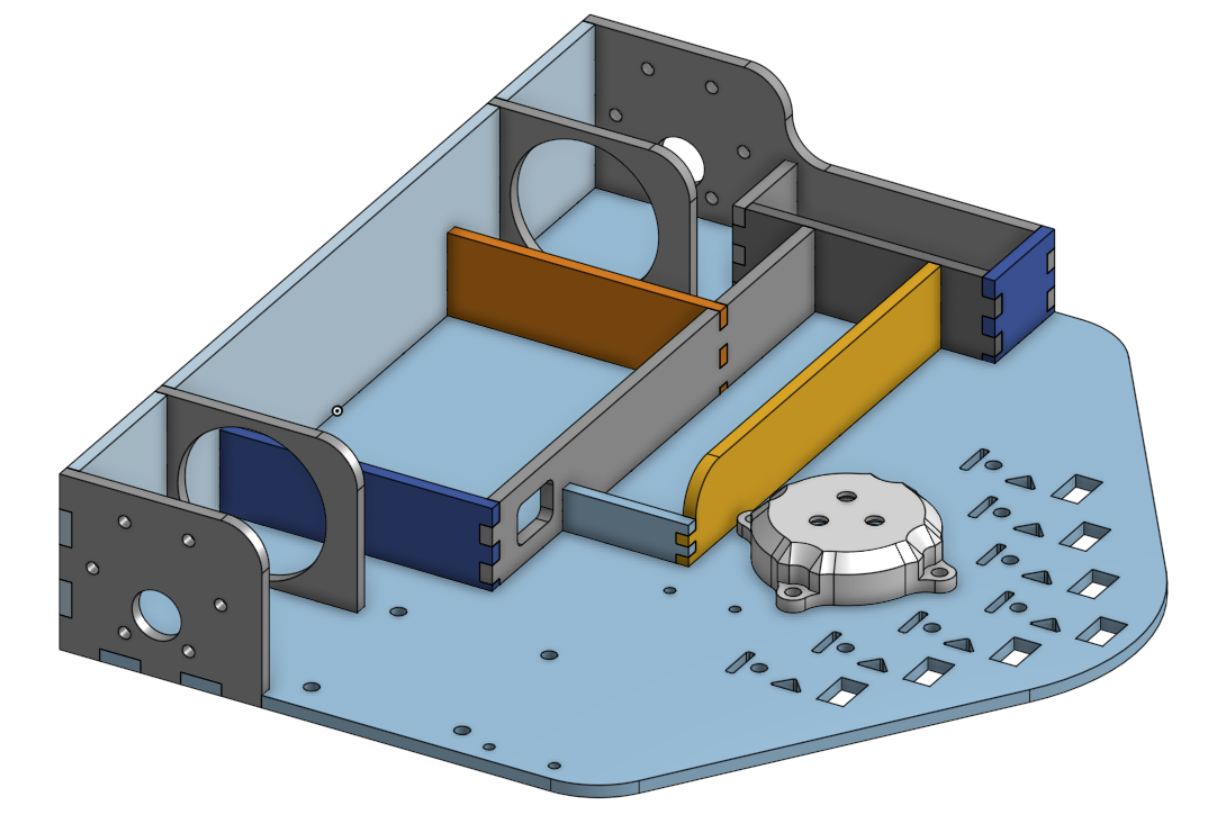

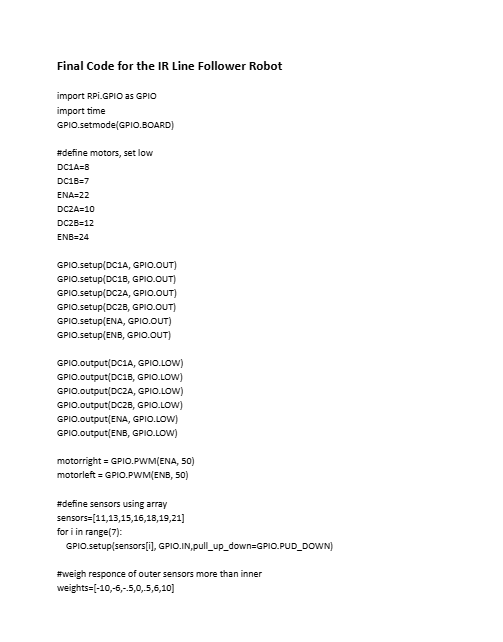

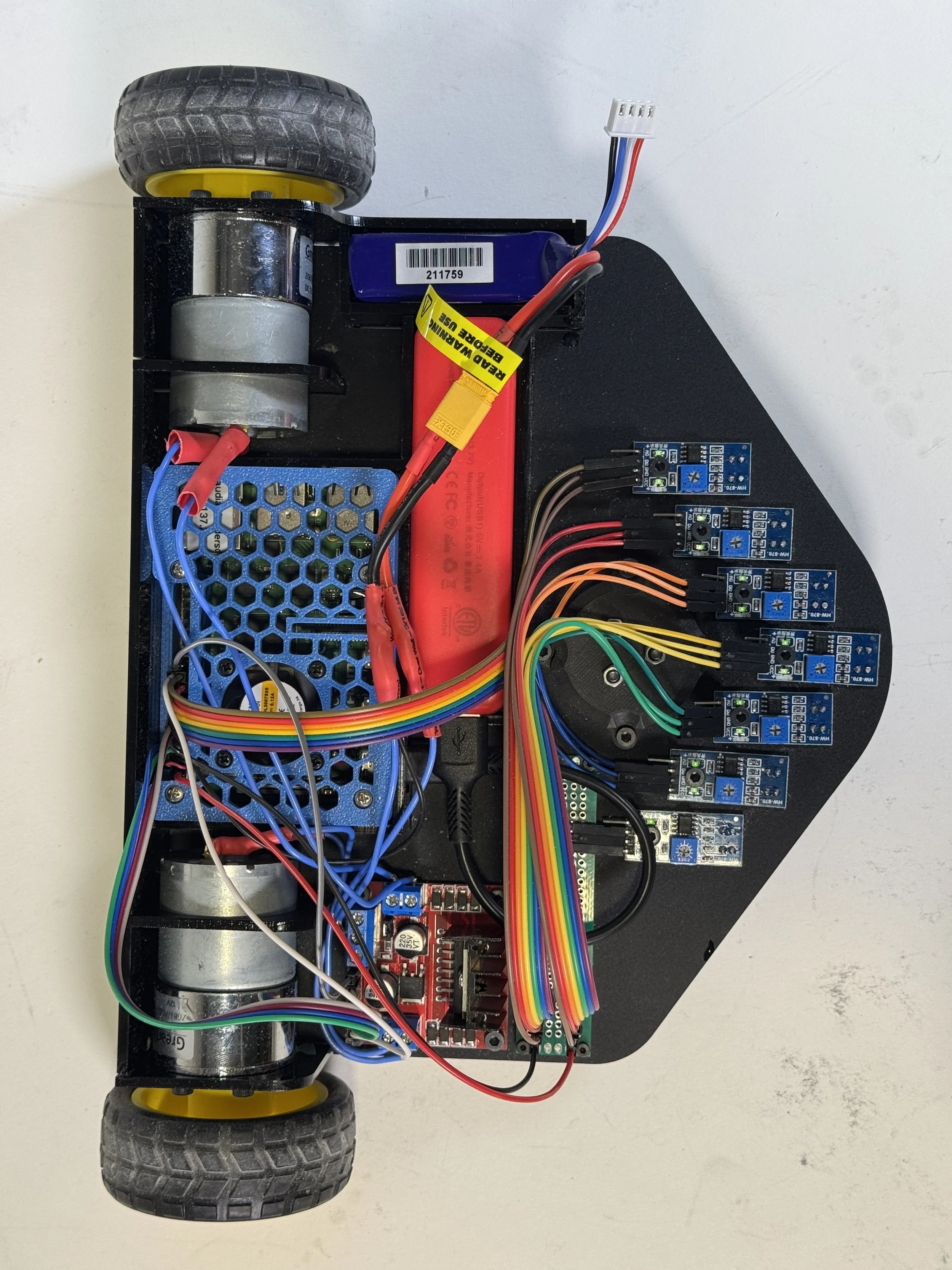

Designed the layout of the laser-cut chassis in CAD, along with 3D printed parts to integrate electrical and mechanical components

Used simple finger joints using Onshape’s built-in tools to improve structural rigidity and simplify assembly

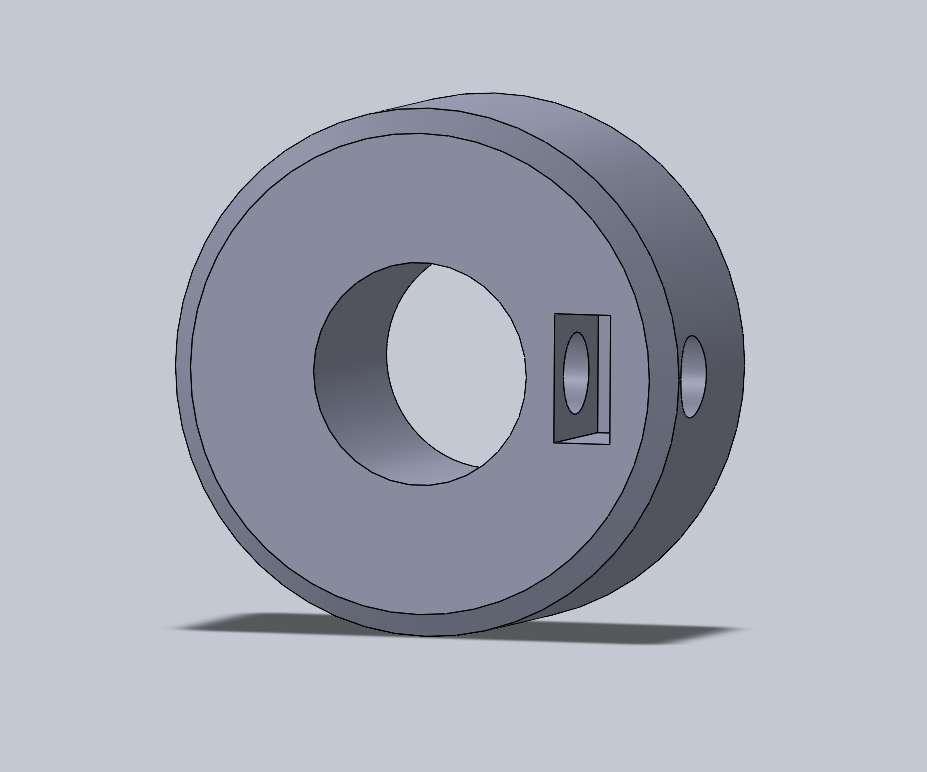

Designed a custom shaft collar using a captive nut to securely mount the wheels to the DC motors

Understanding the Electrical Components Used:

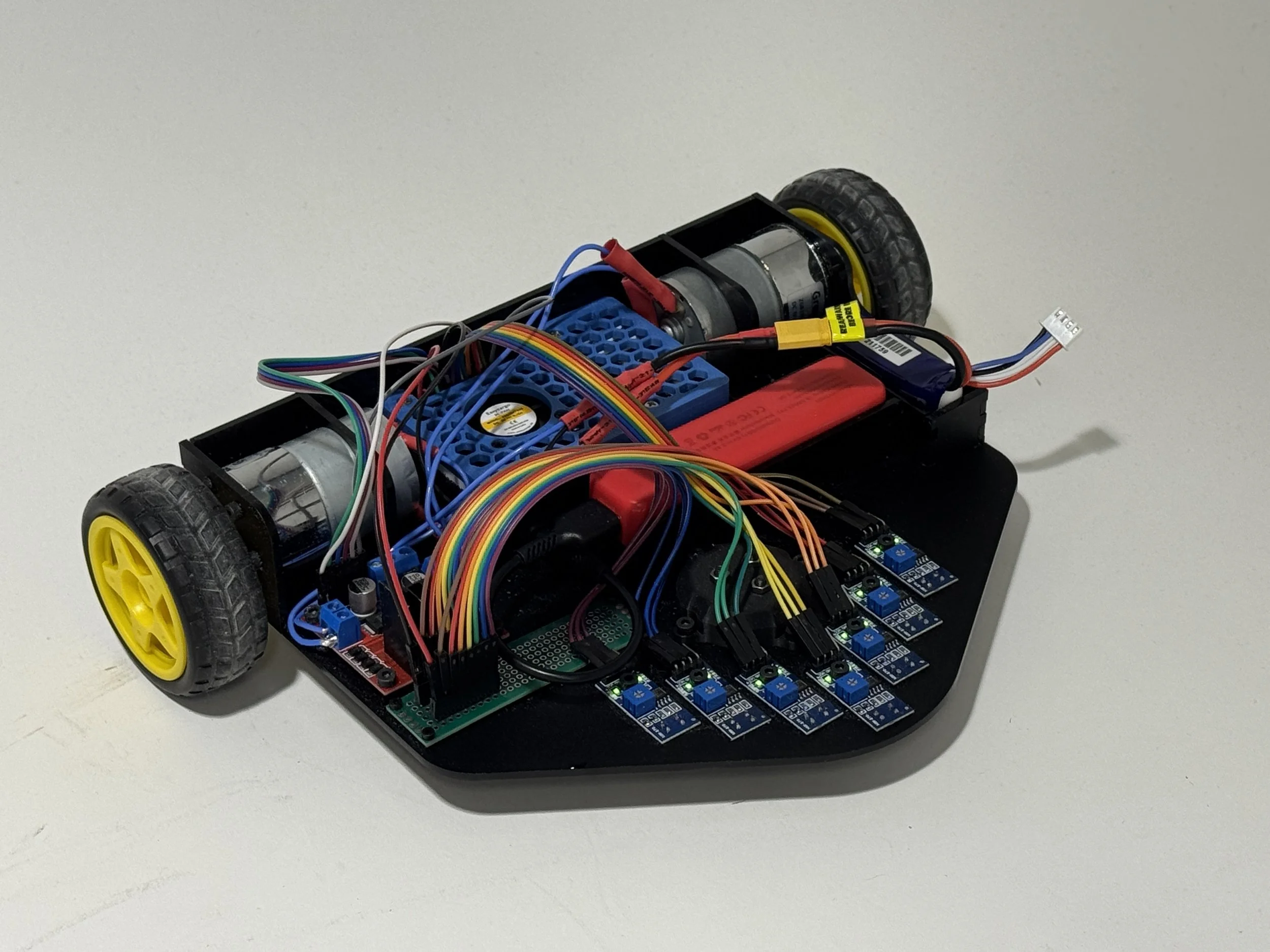

The robot was built around a Raspberry Pi 4, along with a motor driver to power two DC motors

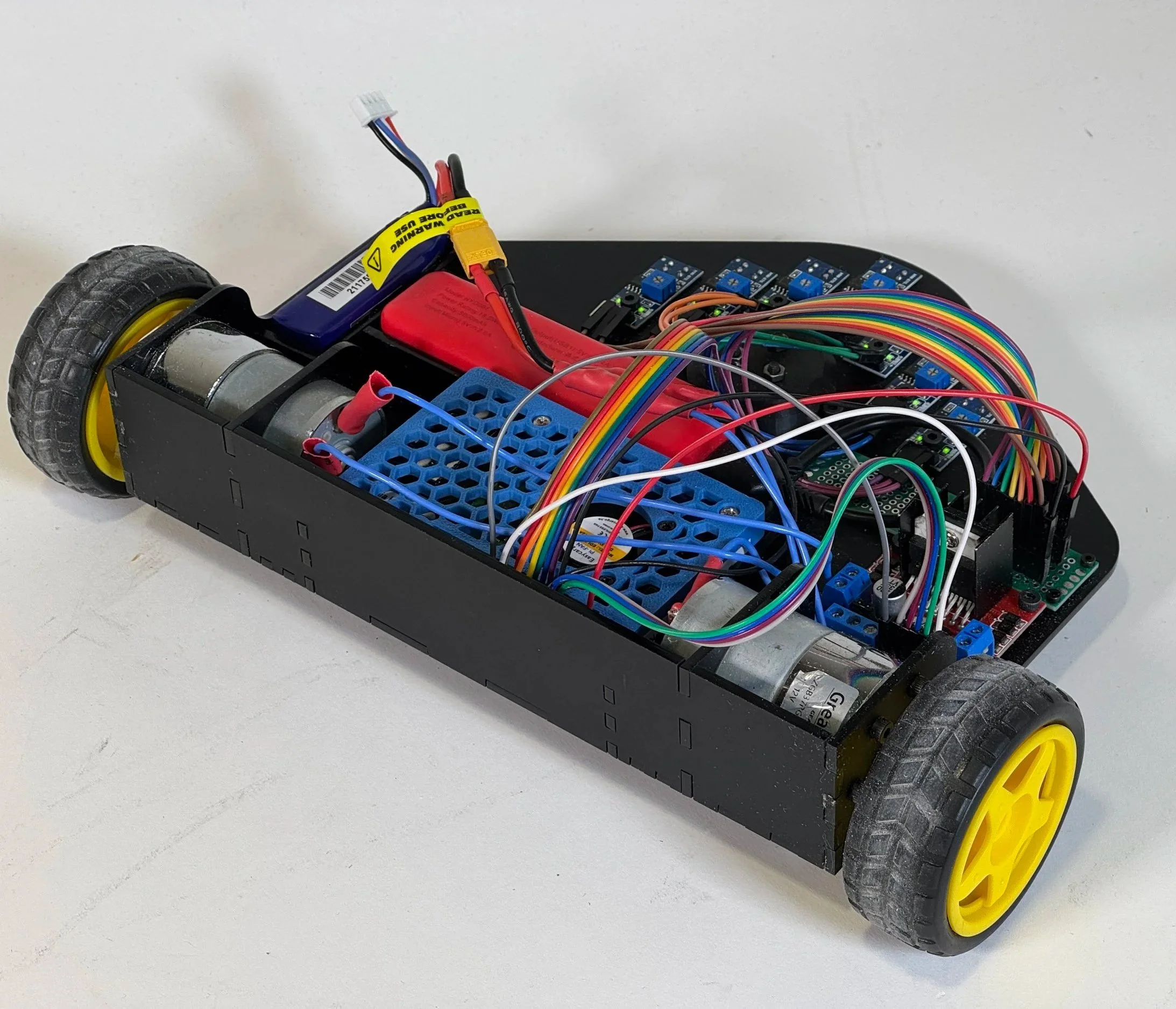

Integrated a 7-TCRT5000 IR array arranged in an arrow pattern to maximize the spatial resolution and hopefully improve line detection

Emits infrared light toward the ground and measures the amount reflected back, allowing it to distinguish between light and dark surfaces (e.g., detecting a black line on a white background for line following)

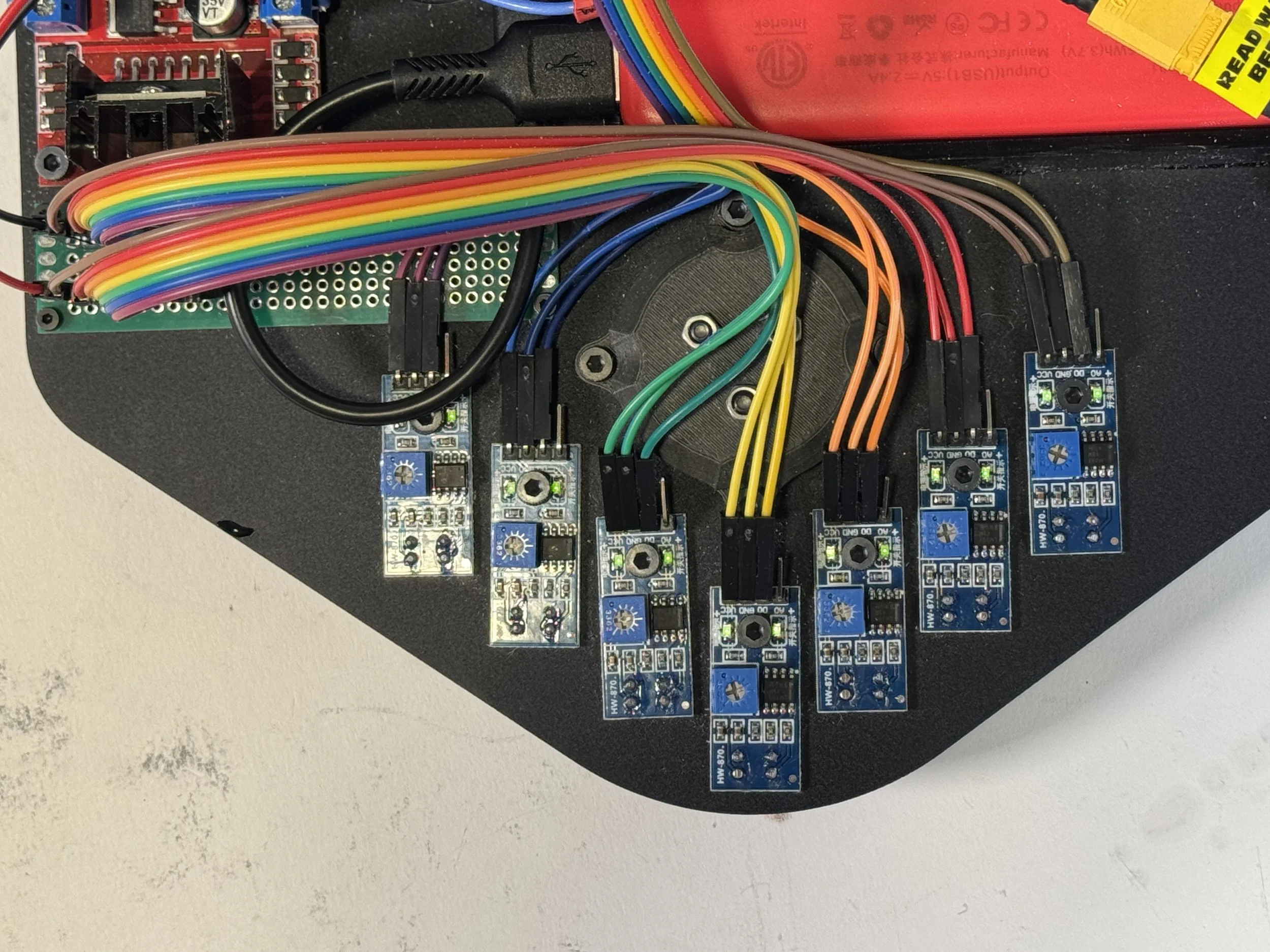

Code and Programming

What Does the Code Do

Configures the Raspberry Pi’s GPIO pins to control two DC motors and read data from a 7-sensor TCRT5000 IR array

Continuously reads the IR sensors to determine the robot’s position relative to the line

Calculates how far the robot is from the center of the line using a weighted average of the active sensors

Uses a PID control algorithm to compute a correction value based on this error

PID controller continuously calculates how far the robot is from the line (proportional), accounts for how long it has been off the line (integral), and predicts how quickly that error is changing (derivative), then combines these three terms to adjust the motor speeds and keep the robot centered on the line

Adjusts the speed and direction of each motor in real time so the robot smoothly steers back toward the line

Repeats this process rapidly, allowing the robot to track the line accurately and respond quickly to curves and disturbances

Click to read the code

Final Design and Demonstration

The robot successfully went through both the easier and more challenging tracks, reliably passing through intersections and tight corners

A full PID control system was implemented, which made for smooth, controlled driving. However, to get consistent tracking required reducing the robot’s speed

The arrow-shaped 7-sensor shape proved to be highly effective, offering precise line localization

Seeing other people’s designs, it would have been smart to line up the wheels closer to the sensors for more immediate responses to the readings

Reflection and Takeaways

Very happy and proud of how this project came out

My main takeaway was gaining a deeper understanding of how a PID control system works and how it smooths and maximizes sensor readings when designing moving systems

I had a lot of trouble while writing code for the robot, trying to write a function to interpret intersections and how to respond. But by discussing the problem with my teammate, we together were able to find a better and simpler solution. A nice reinforcment of how important collaboration and bouncing ideas off one another is so crucial in the prototyping and design process